chris recently finished another parsons table for a client in new orleans. the parsons table is a classic design form, (the link is interesting) and i wrote a blog post about one that will made back in 2010.

this one is going to be covered in shagreen, which under current usage, refers to the rough skin of a southeast asian stingray. it has been used for a long time as a decorative covering for many different kinds of surfaces. the table was delivered recently to mhg studio in long island city, new york.

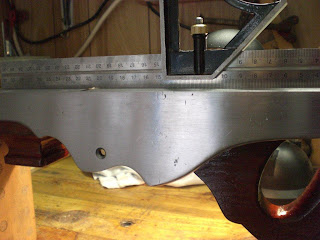

here chris is gluing up the base before adding the mitered top to complete the table.

fortunately, or should i say miraculously, we were able to find will's original corner sample, which kept me from having to describe the various operations required to chris, and he could just have at it.

clean and crispy, with miters everywhere.

we used 3/4" baltic birch and plugged the holes in the bottom of the legs when it was finished.